ABW6-LP

Illinois Refinery

Fouling of pipes and heat exchanging surfaces lowers the thermal efficiency of the system. Fouling also increases the friction losses and induces erosion, corrosion, and energy waste by increasing the demand for a higher flow rate. Other problems include the plugging of spray nozzles, blinding of sensors, analyzers, as well as the wearing down of pump gland seals, scrubbers, misters, membranes, and ion exchanger columns. These issues cause unscheduled shutdowns for maintenance and cleaning and the loss of many production hours.

Filtration is one of the simplest and most convenient ways of solving these problems. TEKLEEN® self-cleaning water filters provide the ultimate solution where dirty water is a problem. The filters operate on line pressure alone. The self-cleaning process is triggered by a pressure differential and is accomplished in seconds without interrupting the main flow. The filters are compact in size and designed to meet a variety of industrial applications. ASME code stamp vessels are also available as an option.

Let us know what your filtration needs are and we'll design the best solution for the job.

Fill out an Application Datasheet to begin.

ABW6-LP

Illinois Refinery

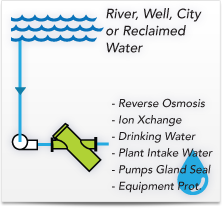

There are many areas within petrochemical processing which use water that requires filtering. The filtered water can then be re-used and the debris properly disposed of. By using a Tekleen self-cleaning automatic filter, this water can be cleaned of debris and solids, provide cooling, pre-filter water for further cleaning, and maintain the operational reliability of piping, spray heads and any devices that water flows through. It can be used as a pre-filter down to 2 microns, protecting R/O and microfiltration systems used for potable water quality production.

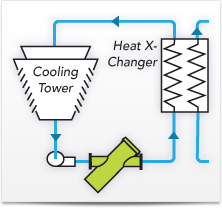

Cooling Water Full Flow (Tower Water, Condenser Water, Chiller)

Utility Water

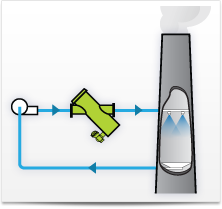

Pollution Control (Wet Scrubber, Waste Water, Recycle)